Manufacturing Techniques

Expression - Distillation - Extraction - Enfleurage - Softact - Synthetic Molecules - Nature Print - Around Table

Diverse manufacturing processes supply the perfumer with the hundreds of ingredients that could potentially enter into a composition. From the first distillation techniques to chemical synthesis, each process is adapted to a type of raw material in the search for its essence.

Expression

Only citrus fruits have peels that are rich enough in natural essences to make the expression process worthwhile. After the peel has been removed from the fruit, itis pierced with numerous small holes and pressed mechanically.

The resulting liquid is allowed to settle and then filtered through wet paper. This separates the aqueous parts from the essential oils. The cold-press process is particularly well suited to oranges, lemons and other citrus fruits whose bright and fresh odor would not survive a treatment involving heat.

Distillation

Distillation relies on evaporation to separate the solids from the various, volatile elements present in a blend. A mixture of water and odoriferous plant material is heated.

The steam , carrying with it the odoriferous elements of the blend, escapes into the distillation column, where it is chilled and then collected in a florentine flask. After a period of decantation, the water separates from the odoriferous elements which are collected and named "essences".

Extraction

When a solvent enters in contact with plant material, it absorbs all the odoriferous substances contained in that material. Traditionally this method - called ENFLEURAGE - involved the use of cold fat. The result of this operation was a pomade or an odoriferous oil. Today fat is replaced by volatile solvents (ethanol, methanol , hexane, toluene, butane or carbon dioxide) which are heated. These solvents are then eliminated through evaporation. What is left is a waxy substance called the concrete. Alcohol is added to the concrete and the mixture is heated and then chilled During this process, plant matter and waxes are removed from the concrete. Once the alcohol is removed through evaporation,all that is left is the absolute.

Enfleurage

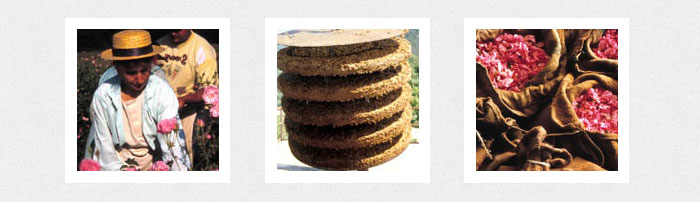

Enfleurage - the oldest extraction process - involved the use of cold fat . Today it has been almost completely abandoned. It was used to extract the oils from fragile flowers such as orange blossoms, jasmin or tuberose.

The hand-picked petals were deposited in a single layer on a pane of glass called "chassis", that was covered with a film of animal fat.

After 24 or 48 hours ( 72 hours for the tuberose), the spent petals were carefully removed. This process was repeated several times, until the fat was saturated with floral oils. Once the enfleurage process was completed, the fatty pomade - saturated with odors - was scraped off and washed with wine spirits. The resulting substance was an infusion.

SOFTACT®

When put under pressure at a temperature below 40o C, CO2 enters a supercritical, fluid state. It assumes the properties of a solvent but has the fluidity of a gaseous substance. Thanks to the SOFTACT®, it is now possible to obtain extracts whose quality and purity are without par. Indeeed, these extracts do not contain any solvents and have not been processed at the usual high temperatures. This is truly a ,SOFT EXTRACTION method.

CO2 makes it possible to extract odoriferous substances of low volatility, such as those contained in spices, for example. CO2 produces excellent results with dry raw materials that don't do well with the traditional extraction techniques.

CO2 used is recycled during the process.

Synthetic molecules

Once a new molecule has been selected - following one or several years of intensive research - the most sophisticated techniques are applied in an effort to manufacture it on a large scale, while ensuring its purity and stability.

The whole manufacturing process for each of these new molecules can vary in length and complexity, but each of them is the object of an extensive, in-depth study.

For instance, to obtain POLYWOOD from pure geraniol, the following steps are necessary : chlorination, distillation, cyclisation, hydrogenation and other esterifications ... a total of six months of various processes that will finally yield the raw material in a state that is usable. The complexity of each chemical reaction as well as the number of successive steps required definitely affect the cost of a raw material and the time needed for manufacturing it. Therefore it is essential to optimize the whole chain of production.

Nature Print®

Nature is an inexhaustible source of inspiration. Scientists and perfumers utilize their creativity and curiosity to indentify new sources: a rare flower with an exquisite perfume, a freshly picked fruit, a spice from the other side of the world. These living scents are inimitable, ephemeral. Once a sample is chosen, its odor must be captured.

For this, scientists use the analysis technique of Nature Print®. To capture a scent, a cartridge is placed within proximity of the fragrant source, which fixes the fragrant molecules that are naturally emmited by the plant. Thus different extracts are carefully harvested which are later selected and evaluated by means of gas chromotography and mass spectrography. Thanks to Nature Print®, we can reconstruct the delicacy and complexity of an odor as close as possible to nature. Nature Print® is to perfumery what photography is to illustration.

.jpg)

Around Table

Marc Chevrier, perfumer

Do you accord a preference to natural or synthetic producs?

Through my island orgins (Vanuatu, Tahiti), I have a passion for natural materials. Through my memory and my olfactive sense, I take particular care in recreating the fragrances of tiara flowers, of frangipani and white ginger...I compose as well with natural essences as I do with synthetic products. I have immense respect for the quality of natural materials. It's a love of the product, of the planet, an exercise in style that demands time, poetry and emotion. We can make beatiful things with references that are close to us while remaining faithful to one's inspiration. For example, when I use Ylang-Ylang in my compositions, I travel from the flower of Madagascar to my laboratory, and that journey makes me dream...

Jean-Pierre Bethouart, perfumer

How do you compose today with the support of new manufacturing techniques?

Perfumes aren't composed like they were in the past. In one century we've gone from a few hundred raw materials to thousands. Thanks to new technologies like "Softact", we treat natural products differently. With "Nature Print" we entirely reformulate the odor of a flower or an ambiance: Infinite nuances enrich our palette. Today chemical synthesis brings the most resources to the perfumer. Often 50 to 90% of ingredients is a composition are derived through this process.

Jean Jacques, perfumer

As a perfumer, what do you expect from technological advances?

In our metier, we work increasingly fast. We have to allay inspiration with impulse to create new notes and to constantly stay abreast of change. It's true that we are on the lookout for new products, whether it's a new molecule, which is rare, or a new quality. It's like discovering a new color as a painter! For example, the contribution of extraction by CO2 is extraordinary. We get materials with headnotes that have a very strong impact, with an optimal respect of natural odor, exceptionally rich cinnamon, freshly ground bay roses... The consumer isn't mistaken here: within seconds he is seduced by this very modern and very qualitative presence. Synthetic raw materials are very precious ingredients for creating new balances, new harmonies and momentum that drive us toward the future. It's also often a reconstituted scent that rekindles a substance from the past, like animal or iris notes, sure values that we modernize and that transport us out of time.

Françis Thibaudeau, President of the Société Française des Parfumeurs

Can a raw material disappear?

In Grasse, we have production sites for jasmine, rose, lavendar and we practice three traditional manufacturing techniques: extraction with solvents, distillation and enfleurage, which we are the only ones who still use. Today as President of the Société Française des Parfumeurs, I'm committed to preserving natural raw materials like the Geraniol or Limonem because some of them are threatened by increasingly strict legislation and considered allergenic without taking into account neither their concentration, nor the degree of risk, which remains minimal (one per 500 million)... at that pace, the Brussels commission SCCNFP* will impose a systematic and fastidious labelling that will run counter to the interests of the market as well as the consumer.

*Scientific Comity Cosmetics & Non-Food Products